Using RFID, brazilian plastics factory reduces order preparation time by 60%

Lucy

2019-07-26 20:15:32

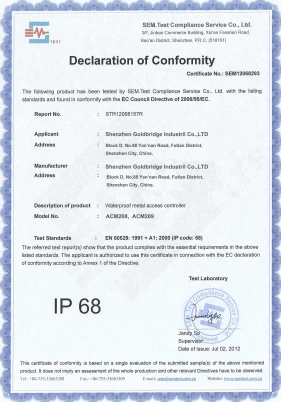

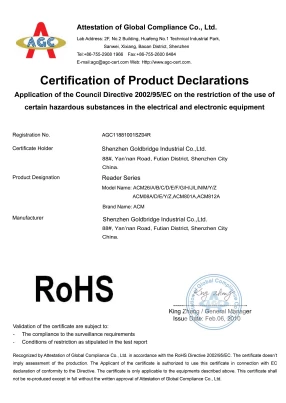

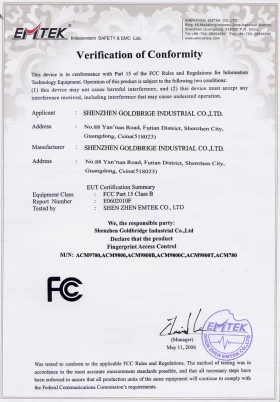

Multinova's foam plastic plant has recently enabled RFID solutions to track its products, using UHF RFID readers for order picking and identification, improving accuracy and efficiency.

Before deploying RFID technology, Multinova's picking and inventory work was done using a barcode reader. With the use of RFID systems, employees need to manually read barcode labels for inventory. The order picking work. Now, they simply fill the foam roll through the reader to complete the inventory and identification work.

The company also measured the effectiveness of the RFID deployment. The results show that RFID systems improve safety and speed up inventory counting and order preparation processes. The company claims that RFID technology reduces staff labor time by 60%. Next, the company will use RFID technology for stock automated inventory and benefit customers.

Currently, after production is completed, each product is transferred to the inventory area via the RFID entrance reader. Then, when loading and delivery, each item will pass through the reader again.

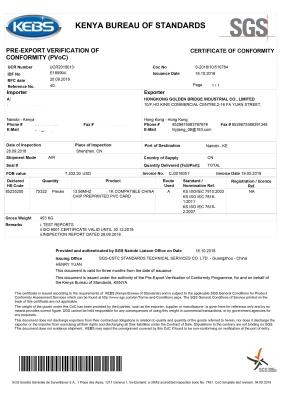

Multinova's material control personnel Paula Germana says the test is working well. Goldbridge can provide the company with the information needed for RFID projects and install the necessary equipment and systems.

Germana claims that the bar code solution has brought many difficulties to the company's operations. She said: "There is a label for each slice of the rolled item. This order preparation and product separation process is time-consuming. Using the RFID system, the reader

The company installed RFID readers in the feed area as well as receiving and shipping terminals. Germana said: "The entrance reader is installed at the receiving and shipping terminals.

Before deploying RFID technology, Multinova's picking and inventory work was done using a barcode reader. With the use of RFID systems, employees need to manually read barcode labels for inventory. The order picking work. Now, they simply fill the foam roll through the reader to complete the inventory and identification work.

The company also measured the effectiveness of the RFID deployment. The results show that RFID systems improve safety and speed up inventory counting and order preparation processes. The company claims that RFID technology reduces staff labor time by 60%. Next, the company will use RFID technology for stock automated inventory and benefit customers.

Currently, after production is completed, each product is transferred to the inventory area via the RFID entrance reader. Then, when loading and delivery, each item will pass through the reader again.

Multinova's material control personnel Paula Germana says the test is working well. Goldbridge can provide the company with the information needed for RFID projects and install the necessary equipment and systems.

Germana claims that the bar code solution has brought many difficulties to the company's operations. She said: "There is a label for each slice of the rolled item. This order preparation and product separation process is time-consuming. Using the RFID system, the reader

The company installed RFID readers in the feed area as well as receiving and shipping terminals. Germana said: "The entrance reader is installed at the receiving and shipping terminals.