Fully automated RFID tags will simplify the linen process

For the hotel industry, the management and processing of linen products is a pain point in the industry. From classification, statistics, packaging to separation of clean or dirty linen, the whole process is complicated, and to a certain extent, it is inevitable to consume more manpower and financial resources.

To solve these pain points, the Venus Group, a textile and linen manufacturer and supplier located in Foothill Ranch, California, and Fujitsu have developed a fully automated RFID tag to deploy the process. These RFID tags can be used to count and identify dirty or clean linen without physical processing.

At present, most of the handicraft production methods are manual, so this requires a large number of employees' labor time. Another point is that the staff may cause certain losses in the process of making linen handicrafts because they are prone to errors.

Reasons for cooperation

Nipun Patel, Director of Strategy and Innovation of Venus Group, said: “For companies such as hotels and industrial laundries that want to lease or provide linen, tracking the inventory of every piece of linen is very challenging, even when the inventory accuracy is not high. Under the circumstances, the tracking process of the linen is also unavoidable to make mistakes. Not to mention, the manual process also requires the physical treatment of each item with relevant cleaning facilities. In fact, if RFID technology is used in the entire washing process, it can be accurate Track every linen product."

According to Venus, after the linen products are affixed with RFID tags, workers do not need to scan a single bar code and can read thousands of linen products in a few seconds. So, this makes it easier for staff in the hotel industry to manage dirty or clean linen, and at the same time improves the tracking process of linen and other assets.

However, if RFID tags are to be attached to each individual item, this process is also very time-consuming. At the same time, sewing the RFID tags onto the linen products by hand will affect the Venus production system to a certain extent. Therefore, in order to better improve the production efficiency of linen products, Venus began to actively cooperate with Fujitsu.

Advantages of RFID tags

Nipun Patel, Director of Strategy and Innovation of Venus Group, said: “For companies such as hotels and industrial laundries that want to lease or provide linen, tracking the inventory of every piece of linen is very challenging, even when the inventory accuracy is not high. Under the circumstances, the tracking process of the linen is also unavoidable to make mistakes. Not to mention, the manual process also requires the physical treatment of each item with relevant cleaning facilities. In fact, if RFID technology is used in the entire washing process, it can be accurate Track every linen product."

According to Venus, after the linen products are affixed with RFID tags, workers do not need to scan a single bar code, and can read thousands of linen products in a few seconds. So, this makes it easier for staff in the hotel industry to manage dirty or clean linen, and at the same time improves the tracking process of linen and other assets.

However, if RFID tags are to be attached to each individual item, this process is also very time-consuming. At the same time, sewing the RFID tags onto the linen products by hand will affect the Venus production system to a certain extent. Therefore, in order to better improve the production efficiency of linen products, Venus began to actively cooperate with Fujitsu.

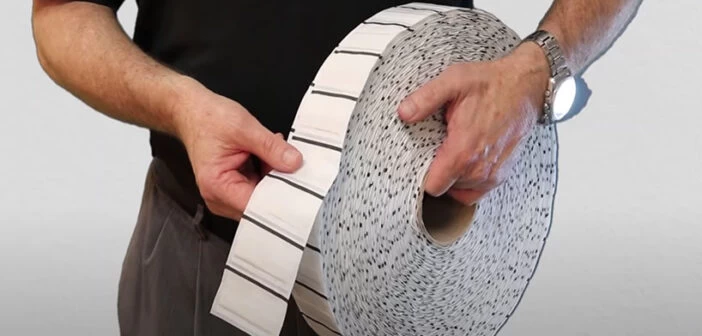

In order to fully automate the process of embedding Fujitsu's RFID tags into Venus linen products, the two companies made a roll of continuous and customized RFID tags in a fabric bag. In other words, each bag contains an embedded RFID linen label and a cutting line with a heat seal. In Venus's automated manufacturing process, RFID linen label rolls are cut off and inserted into the hem of each piece of linen, and then heat-sealed or welded to the article.

Nipun Patel explained: "RFID technology requires customers to invest in RFID data infrastructure, such as Fujitsu or Datamar equipment, and cooperate with textile manufacturers such as Venus to insert a separate RFID tag into each piece of textile. Once the RFID tag is embedded in the cloth In straw products, then, customers can scan each bar code in their washing facilities through RFID technology, and can accurately track the inventory of each piece of linen."

This process reduces the amount of manual labor required to integrate RFID solutions and ensures that each linen product provides consistent quality. Heat sealing can prevent the RFID tag from slipping off the linen product, and the fabric material can prevent the tag from wearing and damaging.

Nipun Patel said: "In cooperation with Fujitsu, Venus has expanded its automated manufacturing process in the United States to realize the automatic insertion of RFID tags into linen products. In fact, RFID technology reduces the physical processing required for each item, and at the same time , Which improves the accuracy of inventory management. So, when Venus has the ability to automate manufacturing, these RFID tags can be added to a series of textiles, such as tablecloths."