RFID Wristbands; Professional Customizers Take You to Understand The Components of RFID wristbands

1. Silicone.

Silica gel is the top environmental protection material. Silicone has excellent elasticity and a smooth touch, making it a material that consumers can feel at ease. The processing method is hydraulic molding, and the material cannot be recycled. The cost is not cheap. If food grade silicone is used, the cost is even higher. This is what high-end smart wristbands use. The made silicone wristband bracelet is not tight and elastic, and has good waterproof sealing performance!

![]()

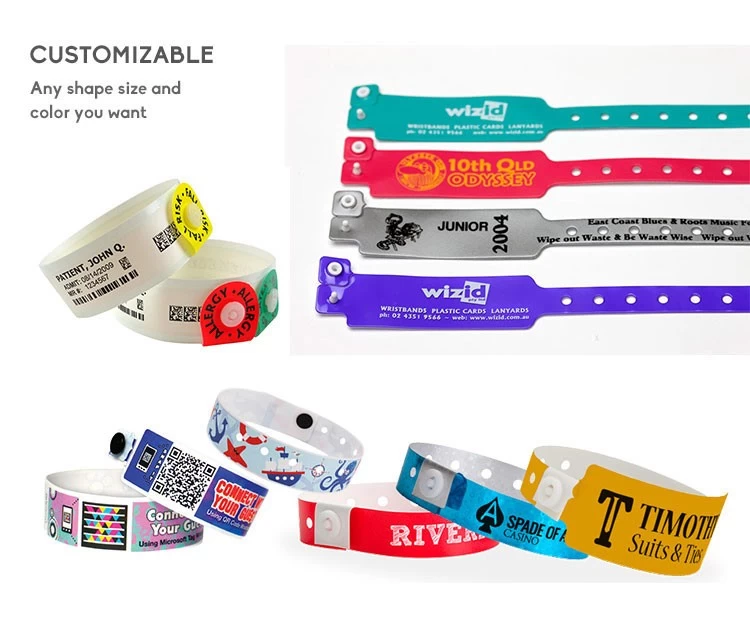

2. PVC

Soft PVC is soft to the touch, brightly colored and inexpensive, but due to an environmental issue of the material, there are relatively few products used for RFID smart wristbands. It is mainly used for handwriting wristbands of disposable PVC film, as medical patient management or personnel management in other occasions. But this material is gradually being replaced.

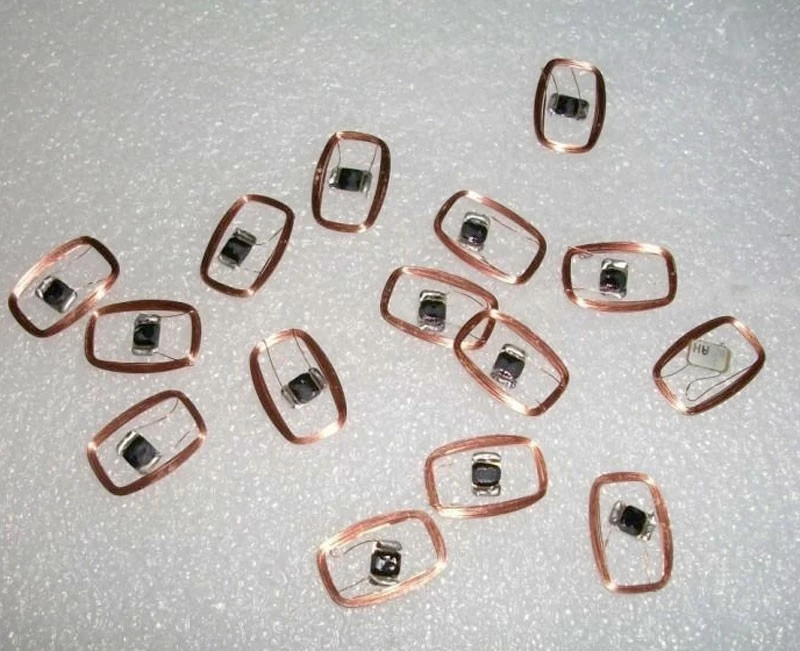

3. RFID chip

In fact, the chip is not the main material of the RFID wristband, but the core material. For example, the identification wristbands used for personnel identification are wristbands made of general materials, such as thermal paper wristbands or PVC film wristbands, with an RFID chip embedded in them, such as medical RFID wristbands and bus card wristbands. Due to the fast reading speed and accurate reading of chip identification, and better protection of personnel privacy, it is widely used in patient management, club personnel management and other occasions.

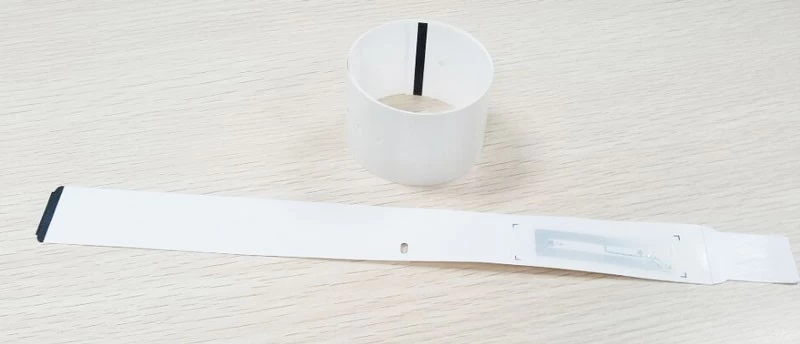

4. Thermal Synthetic Paper

Thermal synthetic paper mainly uses the thermal imaging principle of thermal paper. The most obvious example is the printing receipt in the supermarket. The texture is flexible, the printing is clear, the consumables are simple, the imaging is fast, and the printing content can be customized, which is convenient and fast, so it is widely used in medical identification wristbands for hospital patient management, and also used for ticket management in some parks. layer, durable.

5. Synthetic Paper Wristband

The main difference between this general-purpose synthetic paper wristband and thermal synthetic paper wristband is that it does not use the thermal induction characteristics of thermal paper, but uses the thermal transfer characteristics of the auxiliary material-carbon ribbon, and uses the wristband printer to The print is heated and transferred to the wristband synthetic paper. However, because it is directly transferred to the wristband, the waterproof performance is lower than that of thermal wristbands. If it is a carbon ribbon consumable with better waterproof performance, it requires a relatively high cost. It is also mainly used for medical patient management like thermal wristbands.

6. Tyvek paper

DuPont paper, also known as Nuomi paper, is an environmentally friendly non-woven fabric produced by DuPont in the United States, also known as Tyvek or Tyvek. DuPont paper products combine the advantages of paper, film and fiber, are tough and durable, and have strong tear resistance properties. Moreover, the DuPont paper bracelet can also be customized with various colors, patterns, logos, texts, barcodes, and QR codes. Therefore, DuPont paper wristbands are widely used in concerts, carnivals, training, attractions, theme parks, water parks, playgrounds, KTVs, nightclubs, bars, sports events and other scenes, as a one-time important identification for event personnel.

7. TPE/TPR.

This is actually an elastomeric material based on SEBS. These soft materials are also thermoplastic and can be injection molded. The advantage of the material is that it feels comfortable and soft to the touch, has excellent elasticity, and can simulate the effect of soft and smooth skin. It can also be well bonded with PC plastics. In terms of softness and hardness, it can provide a wide range of Shore 30~90A. The material can be recycled. In terms of cost, it is not cheaper than TPU, and may even be more expensive. The use of a special compounding system makes the material not easy to stick to dust and has good stain resistance. TPE/TPR is a non-toxic, odorless and safe material. As a TPE wristband, it has no sensitization effect on human skin. Meets ISO-10993 testing for the medical industry. Aside from cost considerations, TPE and TPR are ideal wristband materials and alternatives for mid-to-high-end smart bracelet wristbands.

8. TPU or PU

Both of these two materials belong to polyurethane, the difference is that one is thermoplastic (TPU) and the other is cast (PU). PU can also be processed into leather materials. PU leather has a good soft touch and no odor, and can be used as a qualified artificial leather wristband material. The other is TPU. The TPU material has excellent elasticity and can be injection-bonded with the other rigid plastic PC of the bracelet. The cost is also relatively cheap, and the materials can be recycled. The downside is that it's not ideal in terms of soft touch. In terms of hardness selection, usually above 70A, TPU with softer hardness requires high material cost. These two materials are mainly used in smart bracelets.