RFID for medical consumables: a closed loop between patients, suppliers and products

It can be done with RFID for consumables, operators and patients. An RFID system that identifies people and products can enable medical device manufacturers to improve the security of their systems, track the source of consumables, and improve user satisfaction.

Medical Consumables Certification Scheme

Consumables used in clinical settings include drugs, non-drug therapies (such as IV bags), and a wide range of medical supplies and equipment such as syringes, needles, catheters, tubing, and tape. Manufacturers of medical equipment that use or distribute consumables such as infusion pumps have a vested interest in ensuring that their equipment uses materials correctly.

Medical device manufacturers are not allowed to produce drugs or consumables on their own. But in order to improve patient safety and protect the integrity of their equipment, they still need to ensure that medicines or consumables come from approved suppliers and meet equipment specifications and quality and safety standards.

These equipment manufacturers can use powerful consumable certification solutions to help their buyers reduce medical errors and streamline work processes. The consumable certification program can benefit medical device manufacturers, partners and their customers in a variety of ways.

The correct consumables certification solution can:

Protect the consumable supply process of equipment manufacturers or approved suppliers;

Ensure that only approved and unexpired drugs and consumables are used to improve patient safety;

Provide better inventory management for hospitals and use process tracking for suppliers.

How it works: Use RFID to track medical consumables

The main principle of RFID technology is that an RFID reader reads the signal from an RFID transponder, which can be integrated into a card (such as an ID badge), a token (such as a key fob) or a tag.

In order to facilitate the identification of consumables, RFID tags can be embedded in product tags, and use HF or LF radio waves to transmit information to the RFID reader. Some RFID readers can also read Bluetooth Low Energy (BLE) or NFC signals in smartphones.

Correspondingly, RFID readers can also be directly embedded in devices that use consumables to provide automated integrated solutions without user intervention. Or, using an RFID reader as an external connection device, the user only needs to scan the RFID tag on the packaging or consumable label before installation—it takes less than a second to complete this process.

The RFID system can also be set to alert when the wrong medicine is assembled or the product expires. For connected devices, the reader can also send information to the back-end system for inventory management.

Closed loop: connect patient ID, supplier ID and medical products

The RFID reader used for consumable identification can also be used to identify personnel. Clinical staff usually need to carry ID badges to enter buildings and safe areas within the building. The ID badge can also be used to authenticate users of medical equipment.

In a closed-loop scenario, the same RFID reader can identify clinicians, patients, and consumables. Suppose the nurse sets up the infusion pump for the patient. The nurse swipes his ID badge on the infusion pump embedded with the reader, the infusion pump can verify his user ID and confirm whether it is an authorized user, thereby unlocking the device control. Then, he scans the RFID tag embedded in the patient's bracelet to identify the patient he is treating. Finally, he scans the medication before injecting it into the infusion pump.

This complete system not only improves patient safety, but also reduces medical errors and simplifies the hospital billing process. The functions it can achieve include:

Ensure that only trained and authorized users can use medical equipment;

Accurately link the use of consumables or drugs with the patient for correct billing;

Automatically update the electronic health record (HER) by recording the medications and treatment courses provided;

Reduce medical errors by alerting to abnormal conditions such as incorrect medication injection, expired medication, or mismatch between medication and the patient.

The benefits of RFID for medical treatment

Compared with manual input, barcodes or other consumable authentication methods, RFID has significant advantages.

RFID is safer and more reliable than barcodes or printed two-dimensional codes, which are easily forged and easily damaged by tearing, wrinkling, or moisture. The encryption function of RFID can be used for highly secure data transmission, and it is almost impossible to be forged. This ensures that only consumables produced by the equipment manufacturer or approved suppliers can be used in the equipment.

RFID solves the human error caused by manually entering the product number, and allows users to complete their work quickly, easily, and without barriers. This speeds up the busy workflow of clinicians and improves user satisfaction.

RFID stores more information than barcodes, QR codes, or manually entered numbers. In addition to product numbers, RFID tags can also store information such as batch numbers, manufacturing dates, expiration dates, and other unique identifiers. The manufacturer or the purchasing unit of the hospital can use this additional information to track usage.

RFID technology is highly efficient and contactless, minimizing contact points that may be contaminated in the clinical environment.

Choosing the right RFID reader for medical consumables

There are many types of RFID readers on the market, but they are not exactly the same. Many reader manufacturers make readers that can only adapt to their own transponder technology. This is a serious limitation for equipment manufacturers who sell to the international market or cater to suppliers or end users who have their own transponder technology preferences.

When choosing an RFID reader for medical consumables authentication, medical device manufacturers should consider multiple factors.

First, how many transponder technologies does the reader support? Looking for a multi-technology reader that supports LF and HF technologies from all major manufacturers around the world for maximum flexibility. This is especially important if the medical device manufacturer cooperates with multiple third-party consumable suppliers, or wants to use the same device to enable user and consumable verification. If the end user is using a smart phone for personnel identification, please make sure that the reader is also compatible with BLE and NFC.

Second, is it easy to update the reader? This may require updates to add transponder technology or address emerging security issues. Those readers that support contactless update or remote update will extend the life of the device.

Third, does the device have the correct dimensions, communication interface and working power requirements? A suitable reader should be easily embedded in the device without major design or engineering changes.

Fourth, does the reader support advanced encryption and custom configuration? A reader with a powerful software package should have security configuration and custom behavior options, such as setting light and sound sequences for user feedback.

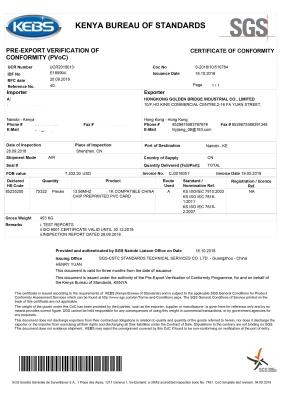

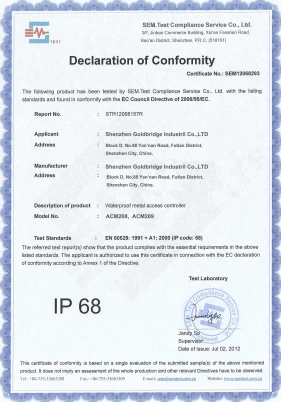

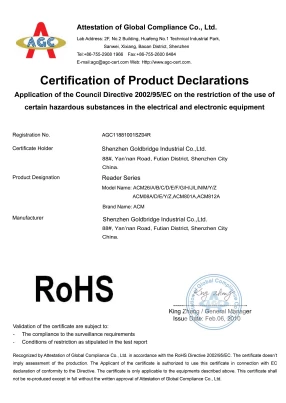

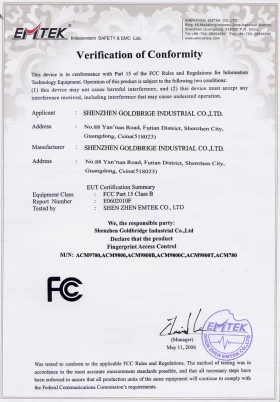

Fifth, is the reader certified for use in all areas where medical equipment is used? Choosing a reader that has been certified for sales in the target market will speed up the time to market for medical devices and simplify the sales process.